USES :

for treatment of hospital medical waste on site.

» Steam sterilization process without release of toxic fumes, gases to atmosphere.

» After the autoclaving process is complete the sterilized waste may then be shredded, and transported to landfill.

» More controlled & safe method of waste management for hospitals & commercial sites.

STERILIZATION PROCESS :

» The sterilization of biomedical waste is done with the help of saturated steam at the temperature of 121°C/ 134°C.

» The sterilizer is operated by steam supplied from the central boiler or by in -built electric steam generator.

» HPHV process ensures good penetration of the steam & reduces the cycle time by evacuating air by vacuum pump.

» Optional automatic control unit to control & indicate pressure, temperature & time during the the process.

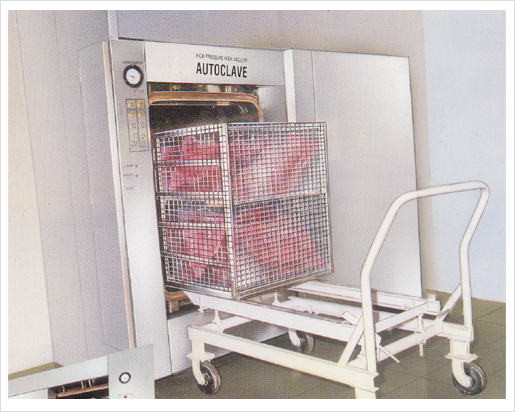

» The loading & unloading carriage is made of stainless steel and it is designed to slide easily from chamber to trolley.

The floor trolley is made of M.S. (Painted).

SHREDDING SYSTEM (OPTIONAL) :

» It can be supplied with rotary shredding system to reduce the size of sterilized waste & make it un-recognizable.

STERILIZER SIZES & CAPACITIES :

» Fabwell Autoclave range in size cross-section of 1½’ X 1½’ To 4’ X 4’ & can treat Waste from 25 Kg To 350 Kg per Hour

(It can be increased as per customer requirements).

CONSTRUCTION :

» The Chamber & Door are made of heavy duty stainless steel

» Piping & Fitting are of Stainless Steel & Bronze

» Loading Carriage is made of SS with removable shelves

DOORS :

» Unit can have a single or double door with gasket of silicon rubber

» Doors can be automatic sliding type or hinged manually opened.