VARIETY OF CONTAINERS

flexible without compromises

PRODUCT QUALITY

one system for all requirements

FOOD SAFETY

oxygen free processing

Today's markets continuously demand new packaging materials for the presentation of shelf stable foodstuffs. Custom tailored solutions, convincing with regard to economics, performance and quality, are more important than ever. Based on more than 100 years of experience and a steady, innovative development of automated systems, STOCK offers individually designed solutions to customers. First-class references around the globe rely on this proven Technology.

Now STOCK Retorts are manufactured in India by STERDILL with technical Know-how from Germany.

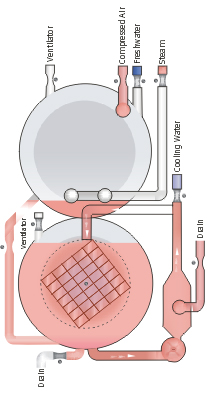

Energy contained in the storage vessel allows for extremely fast temperature come-up-time.

Water envelops the containers - even temperature penetration into the product from all sides.

Optimized water circulation system guarantees homogenous temperature distribution. Buoyancy in full water immersion relieves sensible containers as semi-rigid trays, pouches etc. Counter pressure control with steam in the storage vessel avoids pressure peaks and minimizes stress to packaging material.

Containers are at no process phase in contact with air - oxidation of products is securely excluded. Even, gentle but nevertheless fast cooling avoids thermal shock and post-sterilisation cooking effect.

High temperatures, transferred swiftly into the product, ensure that the required lethality effect (F-value) is obtained as fast as possible.

» The main advantages of the Full Water Immersion system.

» Forced convection due to rotary operation accelerates the heat transfer to the coldest spot in the containers, even with products of higher viscosity.

» Short process times preserve natural quality, vitamins and nutritional values.

» Agitation of the product during heating prevents burning on the container walls.

» Rotation with an intensely mixed process water environment with its optimal heat transfer ensures the HTST

(high temperature-short time) processing of most Products.

| Variants for all requirements | ||

| Type | Diameter | Cages/gross volume litre |

| Rotomat | SRZ 1100 | 2/730 4/1460 |

| Autovap | SAZ 1100 | 2/730 4/1460 |

Optionals :

Heat exchangers for Indirect Heating OR Cooling significantly simplifies the incorporation of the retorts into energy and Water recovery systems

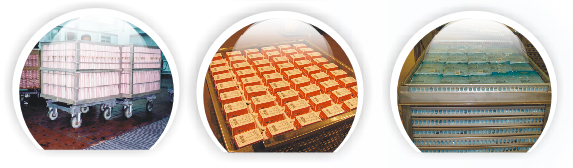

Loading & unloading Equipments

As per your need

We also offer any other chamber dimensions/specifications designed for special applications/requirements.